Rokotech - has been committed to improving the level of precision manufacturing technology

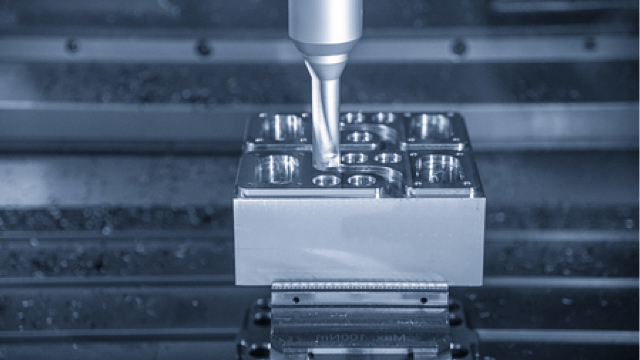

In the mold factory, CNC machining center is mainly used for the processing of die key parts such as die core and insert and copper male. The quality of die core and insert directly determines the quality of die forming part.

Influencing factors of demoulding slope of injection molded products

1) The size of demoulding angle depends on the performance of injection molded products, product geometry, such as product height or depth, wall thickness and cavity surface state, such as surface roughness, processing grain, etc.

2) The draft angle of hard plastic is larger than that of soft plastic;

3) The shape of injection molded products is complex, or the plastic parts with more molding holes need a large demoulding slope;

4) If the injection molding product is high and the hole is deep, take a small demoulding slope;

5) The wall thickness of injection molded products increases, the force of inner hole to wrap the core is greater, and the draft angle should also be larger.

The company has a new CNC production workshop and a fully automatic production line equipped with 5-axis servo manipulator. In the past few years, Rokotech has obtained a number of invention patents for mold design and mold structure manufacturing.

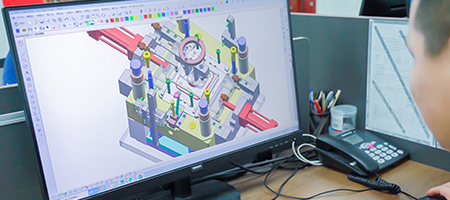

Rokotech has its own R & D team dedicated to breaking through the technical problems of precision manufacturing. It also has more than 50 professional technical production teams to meet the mass customization needs of enterprises;

Before the first mock exam is shipped to your factory, if you need it, we can appoint the engineer to come to the door to debug. You can arrange personnel to Rokotech for training, learning and debugging of a mold, and we will have the wearing parts for customers to replace.

Shenzhen Rokotech Electronic Technology Co., Ltd

Hotline: 0755-23728490

Fax: 0755-23728490

Tel: +86 13825258810 (Mr. An)

Address: floor 1, building 6, Shajing and yixinlianhe Industrial Park, Bao'an District, Shenzhen

Website: www.legaotech.com